SIMPLIFIED INSTRUMENT CONTROL SOFTWARE

- Streamlined method programming enables rapid method design and shorter learning curves

- No need to attend week-long training courses – complete training is conducted on-site in your lab, with a dedicated specialist available for post-install remote support

- Custom method templates for fast programming and implementation of new protocols

FULL PIPETTING DIAGNOSTICS & SAMPLE TRACKING

- Access VVP volumetric measurement data for increased pipetting confidence

- Conduct ‘on-the-fly’ LLD and pipetting diagnostics to ID and resolve common pipetting errors (ie bubbles/clogs/short sample/no sample)

- Full recording of all instrument actions offers a complete audit trail for enhanced process security

FLEXIBLE INSTRUMENT INTERFACE

- No-nonsense interface for controlling all pipetting and gripping functions

- API pathway for communication with third-party devices

- Modular framework supports integration of add-on software and applications

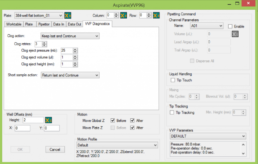

From simple plate stamping routines to the more complex, MM4.0 provides an efficient, straightforward approach to method programming for many workflows.

See a simple Method Manager 4.0 volume transfer

- MM4 Simple Method Example

- Step 1

- Step 2

- Step 3

- Step 4

-

Step 1: Choose tip size and deck location

Load Tip Command: first choose the size and type of tip you will use for the volume required. Tips range in size as 10, 50, 200, 300, 1000 & 1250 µL.

-

Step 2: Aspiration

Aspirate Command: choose the type of plate you wish to access. Here a 96 well plate is shown where the 96 VVP head will access all the wells at once and remove the same 200 µL from each well.

-

Step 3: Dispense

Dispense Command: choose the destination plate type and its location on the deck. This location and plate may also be a variable if this step is within a larger process.

-

Step 4: Eject Tips

Eject Tip Command: eject the tips either back into the enclosed tip box from which they came or eject the tips over a waste shoot to run off the side of the liquid handler or through the deck itself.

Method Manager Integrated VVP Example Applications

Below are some of the most requested questions concerning Method Manager and how it handles certain applications. With the implementation of the VVP tools, new and novel applications are now available. Applications like; Whole Plate Normalization, Whole Blood Sample and Plant/Seed Homogenate Transfers with clog/clog individual well diagnostics and on-the-fly correction, whole plate pooling with all 96 tips, selective high throughput hit picking are all now possible.

A typical example of the Method Manager GUI, graphical user interface, using our Lynx LM900 30 position deck with a 96 VVP Pipetting Tool. Many questions arise of how each of the 96 channels gets individual volume information in and out of the software to take full advantage of the VVP technology.

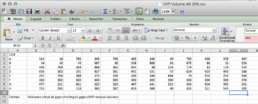

Within the Aspirate Command, you first choose the location of the plate from which you would like to remove the liquid. You may decide to name your plates within your deck, example Source 1 or Purified DNA Source, or you also may choose to name the name a variable if a robotic gripper will continually moving source plate in and out of this position in a fully automated method. A variable will allow the plate to have different volumes associated with every well and can be linked to the bar code of the plate through a database or lookup table.

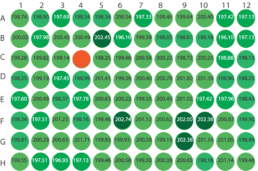

Typical DNA normalization file format used to dilute purified DNA to a standard concentration based on µg/µL.

Method Manager loads up this file and dilutes the sample plate in one shot, the process including tip pickup, aspiration, dispense and eject tips is about 45 seconds. Higher throughput methods will actually have the 96VVP pick up 1250 µL tips, aspirate the full volume of water in to the tip and then multi dispense over multiple plates until the first tip empties.

Transferring challenging samples tests the real limit of a liquid handlers ability to rapidly and accurately react to a situation that would adversely affect the samples ability to enter the tip. Samples like whole blood and plant/seed homogenizes are some of the most variable sample matrix’s to aspirate up into a tip. VVP pipetting tools, the 96VVP and Fixed-8 VVP, allows the user to just click to turn on clot/clog diagnostics.

Since VVP is a closed loop real time measurement of the liquid entering the tip, the system can analyze the flow rate at which the sample is entering the tips and if there is any drop off of this rate over a set limit, the VVP shuts off vacuum to ONLY that individual tip. Since this is live, a clogged tip on the first try is actually visualized in the real time reporting screen.

As shown above, a clot is detected. However, the rest of the channels will continue to aspirate until complete and then the system will re-try the erred well. In this case, the head will rise out of the liquid (note: all the tips are attached to the same drive so all move up and down together, no independent Z drive) the erred sample channel will clear itself leaving the correctly aspirated channels as they are, and then re-dip the tips into the plate and re-try the erred channel as many times as programmed. Method Manager will even alter where each re-try takes place according the well definition as to not have the tip on top of the found clot material.