Resource Library

Details Lynx’s advantages in protein workflows, including large-volume processing, clog detection, positive pressure extraction, and variable viscosity handling. Designed for high-speed and high-yield protein sample processing.

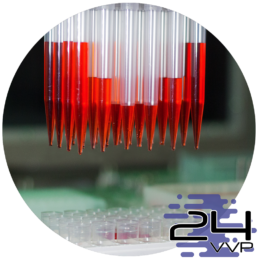

A streamlined solution for cell-free DNA extraction using Dynamic Devices’ 24ST Pipetting Tool and iMagZ magnetic elevator. The system enables high-volume, high-speed, contamination-free processing, improving efficiency in liquid biopsy workflows.

Outlines a high-efficiency, contamination-minimizing workflow for genomic DNA purification using magnetic bead technology on the Lynx platform with in-deck magnet lifters.

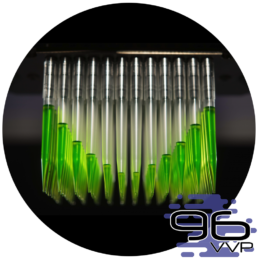

Describes the automation of qPCR and genotyping assay setups using FlexTrough-enabled 96VVP technology for improved speed, reduced contamination, and simplified programming.

Describes the automated extraction of plasmid DNA using microPure LE IMCStips, enabling rapid purification with low endotoxin levels and scalable throughput on Lynx robotic systems.

Introduces SBS-compatible auto-fill reagent reservoirs with integrated sensors and peristaltic pumps. Ensures continuous reagent supply without manual intervention, reducing downtime and human error in automated workflows.

Showcases the SizeX IMCStips workflow for automated buffer exchange, enabling high-throughput desalting and buffer removal across a broad range of protein and enzyme sample types.

This flyer provides an overview of custom automation tables and teach blocks designed to simplify deck alignment and pipetting head calibration for Lynx robotic systems. Interchangeable tops allow compatibility with 96, 24, and 384 well formats.

This document describes automated DNA normalization using the Lynx platform’s 96VVP tool, capable of dispensing 96 unique volumes in a single action. Ideal for sample prep before STR amplification, PCR, or sequencing.

Features resin- and magnet-based purification using filter plates, vacuum stations, and the MagRod system. Offers rapid workflows with high yield and purity across multiple well formats.

Describes an integrated solution using Lynx’s 24-channel MCPA and Omega Bio-tek’s Mag-Bind Kit for automated large-volume cfDNA extraction. Enables high-yield recovery without sample splitting for efficient liquid biopsy workflows.

Details the automation of plasmid DNA purification using silica-based PhyTip SPE technology. Integrated with Lynx robotics, the system enables walk-away extraction from cell pellets with high yield and purity.

Highlights fully walk-away size exclusion and buffer exchange workflows using SizeX IMCStips on the Lynx platform, ideal for protein purification and biomolecule cleanup at scale.

Outlines a partnership between Omega Bio-tek and Dynamic Devices to automate plasmid purification from bacterial cultures using the Mag-Bind kit and Lynx platform, reducing manual steps and improving throughput.

Showcases the use of the Lynx 96VVP system for setting up 4×4 combo dose-response experiments with 96 independent volumes. Ideal for DOE, normalization, and dilution processes with timestamped accuracy and full-volume verification.

Enables efficient pooling of NGS libraries using the 96VVP pipetting tool and FlexTrough, reducing pipette actions by up to 90% compared to traditional 8-tip systems.

This document outlines a high-efficiency method for cell clone picking using the Lynx Liquid Handling Robotic Platform equipped with a 96VVP Pipetting Tool. It details the clone selection process from multi-well plates (6 to 384 format), highlights the integration of IonField plasma tip sterilization for contamination-free reuse, and describes how differential aspiration and dispensing can optimize cell line development workflows in a cost-effective, automated manner.

Introduces IMCStips using dispersive solid-phase extraction (dSPE) chemistry with the Dynamic Devices Lynx platform for protein, plasmid, and biomolecule purification with loose resin technology.

Offers a catalog of interface plate options for Lynx systems, including spring, pin, stacking, locking, and combo plates. These plates provide secure and flexible mounting of labware and accessories such as barcode readers, CPAC, and shakers.

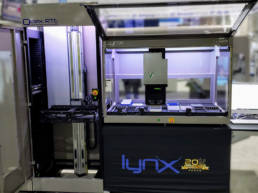

Outlines the Lynx system’s capabilities including volume verification, viscosity detection, positive pressure extraction, and independent channel control. Ideal for improving reliability and speed in varied biological workflows.

Introduces the 24KS, 96KS, and 24KS XL Magnetic Rod Tools for automated bead-based separation in nucleic acid workflows. Compatible with MCPA tools, these rods support high-volume sample handling across various instrument sizes.

A scalable solution for extracting DNA from large volume liquid biopsy samples using the 24VVP tool with 5mL tips and ClickBio’s XBLOK technology.

A joint solution by Omega Bio-tek and Dynamic Devices to purify plasmid DNA from 50 mL cultures in under 90 minutes using Mag-Bind technology and the Lynx LM1200 system with full walkaway automation.

The MAC 10® Original is a high-performance fan filter unit designed for cleanroom environments. It delivers low sound (51 dBA), low energy consumption (310 watts at 90 FPM), and a compact profile under 13 inches. Suitable for ceiling-mounted HEPA filtration, it supports various housing types including Roomside Removable configurations.

The MAC 10® RFAC is a reverse-flow fan filter unit designed to exhaust air and create negative pressure environments. It features a backward-inclined impeller, multiple exhaust configurations, and is ideal for cleanroom containment, contamination control, and modular negative pressure applications.

Highlights the MagLynx system’s ability to deliver faster, cleaner protein purification with higher throughput, reduced plastic use, and easy integration into any lab workflow. Offers flexibility across various plate formats.

Details the range of tip combs, deepwell plates, and elution plates optimized for magnetic particle processing. These consumables are low-binding and designed to improve yield and purity in protein and nucleic acid purification.

Demonstrates an integrated workflow using Covaris adaptive focused acoustics and the Lynx liquid handler for automated and efficient NGS library prep. This approach increases consistency and throughput for high-quality sequencing libraries.

Highlights purification of recombinant GFP from 5 mL lysates using dSPE-based IMCStips on Dynamic Devices’ platform, enabling scalable and walkaway protein processing.

A custom automation workflow integrating Promega’s Maxwell® HT simplyRNA Kit with the Lynx robotic platform. Delivers high-yield RNA extraction from difficult samples like blood and bone marrow.

Describes ultra-fast DNA purification using LGC’s sbeadex Lightning chemistry and the Lynx robotic system, reducing workflows to under 7 minutes per 96-well plate with high-yield recovery from maize and soy lysates.

Features updated SizeX IMCStips technology for size exclusion chromatography with better sample recovery and processing speed using Dynamic Devices’ automation systems.

This datasheet describes the SR10/50 peristaltic pump head system used for fluid transfer in applications like IVD, bioprocessing, and detergents. It supports multiple tubing types and sizes with short-term operation capability, available with DC, AC, and stepper motors.

Focuses on reliable pipetting of heterogeneous biological samples like blood and plant homogenates using VVP closed-loop diagnostics to detect and resolve clogs in real time.

Demonstrates the Lynx system’s role in improving DNA normalization, magnetic bead purification, PCR setup, and error detection. Provides enhanced throughput, accuracy, and contamination control in molecular biology labs.

Boston

Welcome to Dynamic Devices Boston!

Our office/shop is located in the heart of the tech hub on the 128 belt just outside of Boston proper. Located in Bedford, MA we are a customer-focused site with R&D, service, applications and training support. We are an extremely experienced team with well over 50 years in the liquid handling lab automation space. We offer on-site training courses (generic and customized) for learning how to use, program and service our Lynx platform.

Training

Learn What It Takes

Optimize & program your liquid handling workstation like a boss. Dynamic Devices has multiple levels of training sessions.

Types of Training We Offer

OPERATOR TRAINING

Provides a comprehensive overview of programming concepts and terminology of the Method Manager 4 software. Introduces the method development process on the Lynx hardware through lectures, in-class exercises and hands-on training. Participants will have an opportunity to confidently develop processes to conquer laboratory bottlenecks using the Method Manager 4 software with the Lynx robotic liquid handling system.

DEVELOPER TRAINING

Provides an in-depth overview of complex programming concepts of the Method Manager 4 software. Introduces advanced method optimization and integration on the Lynx hardware through lectures, case studies and hands-on training. Participants will have an opportunity to optimize current processes, handle data more effectively, and turn their Lynx into a fully integrated system.

Length: 4 days (in person)

Intended Audience: New users or long-time users in need of a refresher

Length: 4 days (in person)

Intended Audience: Experienced users with programming experience in C#

- Note: C# experience is not mandatory, but we do not train users in C#.

2025 Operator Training Sessions (5 seats per session):

- March 25th – March 28th

- June 24th – June 27th

- September 23rd – September 26th

- November 4th – November 7th

2025 Developer Training Sessions (5 seats per session):

- April 29th – May 2nd

- August 26th – August 29th

- October 21st – October 24th

Lynx Certified Disposable Tips

WE DON’T COMPROMISE ON QUALITY

Lynx-certified disposable tips are manufactured in a GMP clean-room environment. Gamma irradiation and in-line QA visual inspection processes ensure a sterile, superior quality consumable for robust, reproducible pipetting with high accuracy and precision.

STERILE CLEAR TIPS

Lynx uses exclusively high-quality, gamma-irradiated CLEAR polypropylene disposable tips for all pipetting and liquid level detection, eliminating the need for expensive black polycarbonate tips. VVP flow sensor technology allows for robust LLD in both tubes and plates, and can accommodate compromised samples containing clots, bubbles or foam.

SOLID MANDREL DESIGN

Proprietary stainless-steel tip adapters allow for reproducible tip pickup; zero service/wear parts means reduced service and maintenance costs; single design compatible with all Lynx consumables tips.

STANDARD BOXES

All Lynx-brand tips are housed in ANSI-standard containers, allowing for placement anywhere on the deck. Tip pick-up directly from sturdy tip boxes eliminates the need for dedicated racks or tip loaders.

NEW DDX SERIES TIPS

The new and improved DDX tip series are designed exclusively for use on our VVP and ST pipetting heads. Enhanced soft tip collars enable a higher integrity seal and a new hard stop design feature provides for robust, reproducible tip pickup.

Lynx-Certified Disposable Tips

Supporting high-performance pipetting for all your application needs

DDX Tips

our premium tip; new design and enhanced hydrophobic resins; unsurpassed pipetting performance and robust tip handling; all sterile

96 FORMAT – FILTERED

96 FORMAT – NON-FILTERED

96 FORMAT – FILTERED – SPECIALTY

24 FORMAT – FILTERED

LXB Tips

our standard consumable; time-tested and trusted in labs for over 5 years; all sterile

96 FORMAT – FILTERED

96 FORMAT – NON-FILTERED

384 FORMAT – FILTERED

384 FORMAT – NON-FILTERED

Method Manager 4.0

SIMPLIFIED INSTRUMENT CONTROL SOFTWARE

- Streamlined method programming enables rapid method design and shorter learning curves

- No need to attend week-long training courses – complete training is conducted on-site in your lab, with a dedicated specialist available for post-install remote support

- Custom method templates for fast programming and implementation of new protocols

FULL PIPETTING DIAGNOSTICS & SAMPLE TRACKING

- Access VVP volumetric measurement data for increased pipetting confidence

- Conduct ‘on-the-fly’ LLD and pipetting diagnostics to ID and resolve common pipetting errors (ie bubbles/clogs/short sample/no sample)

- Full recording of all instrument actions offers a complete audit trail for enhanced process security

FLEXIBLE INSTRUMENT INTERFACE

- No-nonsense interface for controlling all pipetting and gripping functions

- API pathway for communication with third-party devices

- Modular framework supports integration of add-on software and applications

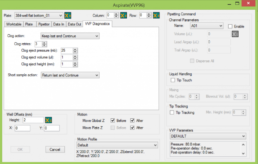

From simple plate stamping routines to the more complex, MM4.0 provides an efficient, straightforward approach to method programming for many workflows.

See a simple Method Manager 4.0 volume transfer

- MM4 Simple Method Example

- Step 1

- Step 2

- Step 3

- Step 4

-

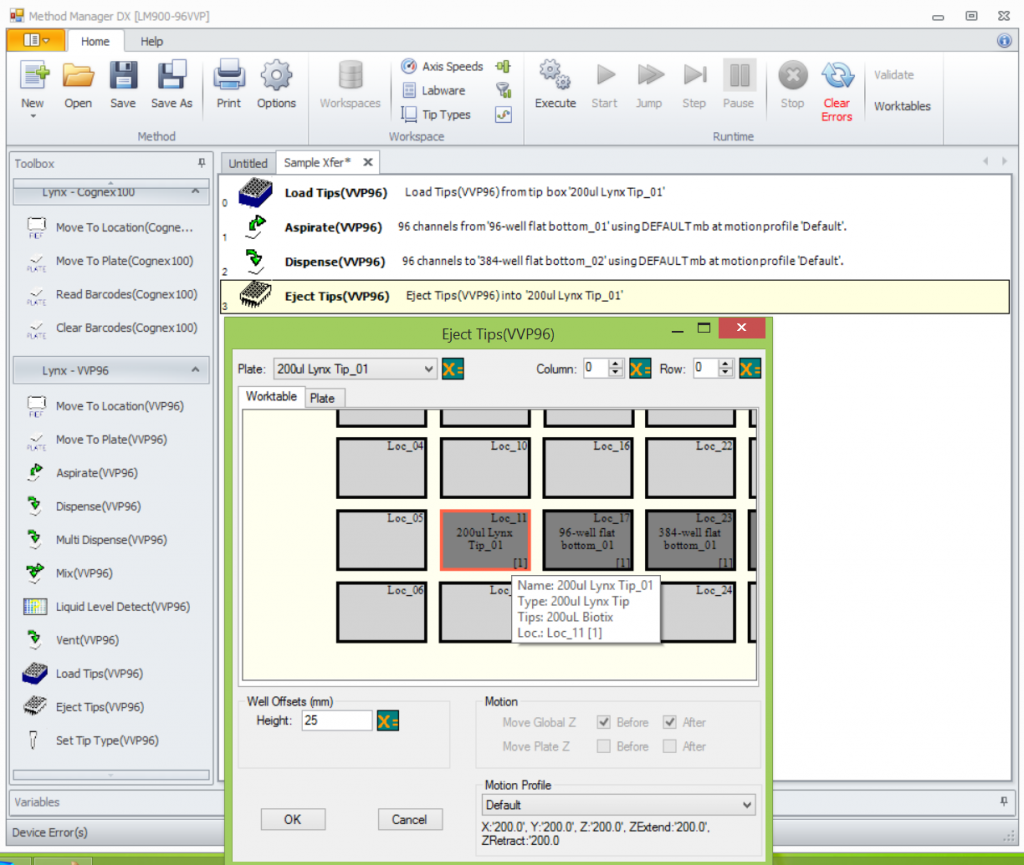

Step 1: Choose tip size and deck location

Load Tip Command: first choose the size and type of tip you will use for the volume required. Tips range in size as 10, 50, 200, 300, 1000 & 1250 µL.

-

Step 2: Aspiration

Aspirate Command: choose the type of plate you wish to access. Here a 96 well plate is shown where the 96 VVP head will access all the wells at once and remove the same 200 µL from each well.

-

Step 3: Dispense

Dispense Command: choose the destination plate type and its location on the deck. This location and plate may also be a variable if this step is within a larger process.

-

Step 4: Eject Tips

Eject Tip Command: eject the tips either back into the enclosed tip box from which they came or eject the tips over a waste shoot to run off the side of the liquid handler or through the deck itself.

Method Manager Integrated VVP Example Applications

Below are some of the most requested questions concerning Method Manager and how it handles certain applications. With the implementation of the VVP tools, new and novel applications are now available. Applications like; Whole Plate Normalization, Whole Blood Sample and Plant/Seed Homogenate Transfers with clog/clog individual well diagnostics and on-the-fly correction, whole plate pooling with all 96 tips, selective high throughput hit picking are all now possible.

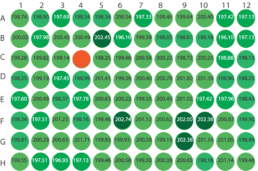

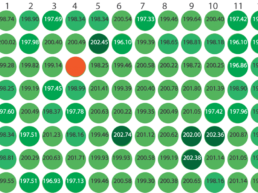

A typical example of the Method Manager GUI, graphical user interface, using our Lynx LM900 30 position deck with a 96 VVP Pipetting Tool. Many questions arise of how each of the 96 channels gets individual volume information in and out of the software to take full advantage of the VVP technology.

Within the Aspirate Command, you first choose the location of the plate from which you would like to remove the liquid. You may decide to name your plates within your deck, example Source 1 or Purified DNA Source, or you also may choose to name the name a variable if a robotic gripper will continually moving source plate in and out of this position in a fully automated method. A variable will allow the plate to have different volumes associated with every well and can be linked to the bar code of the plate through a database or lookup table.

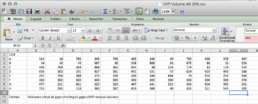

Typical DNA normalization file format used to dilute purified DNA to a standard concentration based on µg/µL.

Method Manager loads up this file and dilutes the sample plate in one shot, the process including tip pickup, aspiration, dispense and eject tips is about 45 seconds. Higher throughput methods will actually have the 96VVP pick up 1250 µL tips, aspirate the full volume of water in to the tip and then multi dispense over multiple plates until the first tip empties.

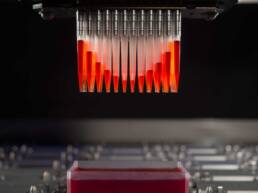

Transferring challenging samples tests the real limit of a liquid handlers ability to rapidly and accurately react to a situation that would adversely affect the samples ability to enter the tip. Samples like whole blood and plant/seed homogenizes are some of the most variable sample matrix’s to aspirate up into a tip. VVP pipetting tools, the 96VVP and Fixed-8 VVP, allows the user to just click to turn on clot/clog diagnostics.

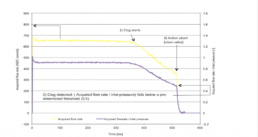

Since VVP is a closed loop real time measurement of the liquid entering the tip, the system can analyze the flow rate at which the sample is entering the tips and if there is any drop off of this rate over a set limit, the VVP shuts off vacuum to ONLY that individual tip. Since this is live, a clogged tip on the first try is actually visualized in the real time reporting screen.

As shown above, a clot is detected. However, the rest of the channels will continue to aspirate until complete and then the system will re-try the erred well. In this case, the head will rise out of the liquid (note: all the tips are attached to the same drive so all move up and down together, no independent Z drive) the erred sample channel will clear itself leaving the correctly aspirated channels as they are, and then re-dip the tips into the plate and re-try the erred channel as many times as programmed. Method Manager will even alter where each re-try takes place according the well definition as to not have the tip on top of the found clot material.

INTERESTED IN SEEING A DEMO

LET’S SET ONE UP!

Lynx Platform Deck Sizes

Lynx platform deck sizes offer space efficiency & workflow flexibility with 5 chassis sizes to choose from!

The Lynx LM platform sets a new standard in space efficiency and workflow flexibility with multiple platform sizes, all featuring:

compact Y-axis for pipetting access to more common positions

direct Z-drive systems for robust tip pick-up and ejection

open architecture for superior deck layout flexibility and ease of loading

standard ANSI-compliant labware mounting system for simplified location of plates, tips and reservoirs

All controlled with user-friendly MethodManager4 instrument control software

The largest of our platforms for high capacity walk away times.

The Lynx LM1800 offers 1800 mm of X-axis travel while requiring only 75.7” of bench space. 60-66 microplate position capacity with pipetting access to 42 common positions in a dual arm system

Our medium capacity workstation for fully automated workflows.

The Lynx LM1200 offers 1200 mm of X-axis travel while requiring only 52.2” of bench space. 42 microplate position capacity with pipetting access up to 18 common positions depending on the arm configuration.

Our most popular size unit for lower capacity workflows, offering 30 deck positions in only 3 feet of bench space.

The Lynx LM900 offers 900 mm of X-axis travel while requiring only 40.5” of bench space. 30 microplate position capacity.

Dual side access for external robot integration and full manual access, offering the 96/f8 VVP Pipetting Tools & 96/384 ST Pipetting Tools.

Designed for complex integration projects, the LM730i open architecture frame provides an external gripping robot access to 9-12 on-deck positions. With a total of 18 positions, the rear positions may be used to hold wash stations, reagent reservoirs, disposable tip racks or other labware/modules.

Our compact liquid handling platforms, the LM700 offers a small footprint and exclusively uses ST Pipetting Tools.

The Lynx LM700 offers 700 mm of X-axis travel while requiring only 27.6” of bench space. 12 microplate position capacity with pipetting access to all positions. Single arm system only. Largest tip size = 300 μL.

Applications

Lynx – Supporting Your Science

Lynx supports a broad spectrum of applications within the Life and Clinical laboratory sciences, as well as Applied markets. Our cross-functional team of experts work with you to design an automated workflow that is robust and practical. And our ‘zero bias’ policy towards any one peripheral device manufacturer ensures your solution is truly best suited to meet your specific operational and productivity requirements.

Unlock the Future of Automated Liquid Handling: Watch SLAS Spotlight 2025 Sessions

Discover the future of automated liquid handling with Dynamic Devices at SLAS 2025! Our SLAS Spotlight sessions showcase the power of Lynx in transforming laboratory applications. Watch leading scientists and automation experts reveal cutting-edge solutions that streamline processes and improve accuracy. Don’t miss this opportunity to see how Lynx is revolutionizing the way labs operate. Watch the sessions now and explore more on how Lynx is enhancing automated applications.

GENOMICS

- DNA/RNA Extraction & Purification

- Utilize leading vendor chemistries & methods or your own proprietary

- Supporting range of protocols, from magnetic bead to vacuum filtration to positive pressure

- NA Quantification & Normalization

- Conduct fluorescence intensity or absorbance-based quant

- VVP independent volumes enable 96-well plate normalizations < 45 seconds!

- qPCR/PCR Setup

- reduce reaction volumes to save precious sample and costly reagents/enzymes

- integrate the thermal cycler best suited to your needs

- NGS Sample & Library Prep

- High quality sample prep for high integrity libraries

- VVP technology affords unparalleled speed in pooling

- Other: CRISPR Setup / NA Expression Profiling / MicroArray Setup

- Supporting the Cas-9 workflow

- From cloning to colony picking to genotyping

PROTEOMICS

- LC/MS Sample Prep for research, clinical, forensic & toxicology

- Dilute & Shoot

- SPE; column or plate-based

- LLE

- IHC & ELISA Setup

- Protein Expression & Profiling

CELLOMICS

- Cell Culture & Maintenance

- Cell-line Transfection

- Cell Bioassay Setup

DRUG DISCOVERY

- Coronavirus (COVID-19) Testing

- Coronavirus (COVID-19) Sample Pooling

- Target ID & Validation

- Lead Selection & Lead Op

- Compound Screening & Management

- Fast compound dissolution’s!

- ADMET, Synergy Experiments & more!

APPLIED SCIENCES

- Forensics

- chain-of-custody in every liquid transfer

- 1D and 2D barcode scanning. PCR setup. Normalize in a single step!

- Agriculture

- Lysis, Extraction, Isolation & Purification

- Industrial Chemicals

- Food Technology Services

MICROARRAY

New developments in protein microarray technology provide a flexible tool to study protein-protein, protein-nucleic acid, protein-lipid, enzyme-substrate, and protein-drug interactions. Other types of microarrays also show great potential in diagnostics, protein profiling, and drug identification and validation.

Interested in starting a project together?

We’d love to hear from you.

Technology

Lynx – The Ultimate Partner in Automation

Lynx leverages advanced enabling technologies to enhance liquid handling automation, delivering superior performance, robustness, and data integrity for your automated workflows.

VVP Technology

Award-winning Volume Verified Pipetting (VVP) technology represents the very latest in air-based 8, 24 & 96 multi-channel pipetting.

Highly sensitive in-line flow sensors integrated into each and every channel translates to unique pipetting competencies

Independent Volumes on All Channels

- Superior flexibility for 96 & 24-channel automated liquid handling

- Expands pipetting workflow efficiency by several-fold over traditional tools

- Perform plate normalizations, serial dilutions & other common routines in record time

Direct Volumetric Measurement of Each & Every Transfer

- Ultimate pipetting confidence with real-time volume verification

- Removes the guesswork from automated liquid handling once-and-for-all

- Any liquid, at any volume…with zero liquid class development

Live Pipetting Diagnostics & Error Recovery

- New levels of process security with continuous QC monitoring of all channels

- More robust workflows with advanced user-defined recovery for ‘on-the-fly’ corrections

- Final validation data report captures all pipetting data

How VVP Works

VVP air-based pipetting tools perform all aspirate and dispense functions via precise control of vacuum and positive pressure, respectively.

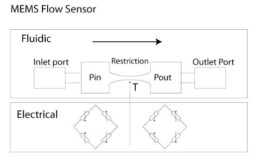

A silicon chip-based MEMS micro-sensor assembly incorporated into each liquid channel measures the pressure differential across a known constriction. Volumetric flow rate is a linear function of this pressure differential, allowing for instantaneous calculation of the actual volume of liquid entering or leaving each tip.

By monitoring and adjusting to volumetric flow in real-time, all pipetting processes can be controlled and finely tuned for any liquid, automatically accommodating for temperature and viscosity differences.

Liquid Level Detection (LLD) with VVP

Independent-channel LLD on all liquid types is performed via controlled micro-releases of air from the distal end of the tip and subsequent monitoring of pressure changes associated with meniscus (or bubble/foam) interference. A residual volume based on the confirmed meniscus height and labware definition is calculated. Any pipetting discrepancies experienced are addressed via several user-defined error recovery options.

Air-based VVP technology accomplishes robust LLD without the need for more expensive carbon-impregnated (capacitance-based LLD) disposable tips. For the best pipetting results, be sure to use D2-brand ‘performance-certified’ clear disposable tips.

Pipetting Diagnostics with VVP

VVP performs continuous millisecond analysis of flow rates for each liquid channel. A disruption in the expected average flow rate, produced either by air entering the channel (i.e. ‘short or no sample’) or a blockage (i.e. clot/clog) triggers an alert.

Diagnosed pipetting errors are addressed automatically ‘on-the-fly’ via user-defined error recovery options.

Independent control of each channel affords the freedom to isolate and disable only the offending channel(s), allowing the method to continue without interruption.

Upon method completion, a final Error Report file is generated.

Advanced Clot/Clog Detection & Correction

Characteristics of the sample matrix are used to set specific flow rate measurement thresholds, allowing optimal detection and recovery from blockages such as clots or clogs. Upon detection, affected channel(s) are disabled and remaining tips finish aspirating. Upon completion, the VVP head is raised, affected tip(s) cleared and an ‘intra-well re-aspiration’ is performed.

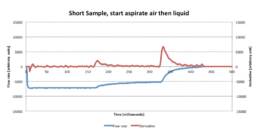

Short Sample/No Sample Detection & Correction

Flow rate changes caused by introduction of air into the sample column during aspiration are used to diagnose a ‘short sample’ or ‘no sample’ specimen. Recovery options include skip the sample, re-aspirate, sample blow-back, or dispense and report the actual volume transferred.

VVP Tools

Featuring next-gen integrated flow sensor technology. Fast and flexible, perfectly suited for liquid handling in single microliter to milliliter volumes.

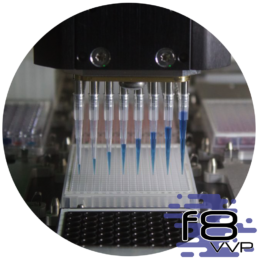

96VVP Pipetting Tool

96 channel (8×12) head; fixed 9mm spacing

- 96 independent volumes with LLD & Pipetting Dx on each channel

- Wide dynamic range: 1.5 μL – 1,250 μL/channel

- 96 volume transfers simultaneously monitored, verified and recorded in real-time

The only 96-channel head on the market with 96 independent volumes, allowing for new levels of flexibility and efficiency. Yields unsurpassed speed in combinatorial pipetting routines, normalization, serial dilutions, pooling, hit picking and complex plate layouts.

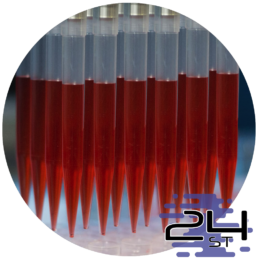

24VVP Pipetting Tool

24 channel (4×6) head; fixed 18mm spacing

- 24 independent volumes with LLD & Pipetting Dx on each channel

- Wide Dynamic Range: 50 μL – 5,000 μL/channel*

- 24 verified volume transfers simultaneously monitored, verified and recorded in real-time

*using D2 performance-certified DDX-24 5mL disposable tips

The only 24-channel head on the market with 5mL/channel capacity. Ideal for applications such as liquid biopsy sample distribution and large volume DNA mag-bead based extraction. 24 independent volumes offers flexibility for more complex pipetting routines.

Fixed 8VVP Pipetting Tool

8 channel (1×8) tool; fixed 9mm spacing

- 8 independent volumes

- Wide Dynamic Range: 1.5 μL – 1,250 μL/channel

- 8 verified volume transfers simultaneously monitored, verified and recorded in real-time

The Lynx’s entry-level VVP tool (f8) transfers 8 independent volumes of liquid with verified volume reporting and full pipetting diagnostics. For samples within microplate format you can now validate your transfers with our fixed-8 tip VVP Pipetting Tool. By eliminating the independent spreading and Z axis capabilities, multiple axis control is reduced, providing a highly economical yet functional VVP pipetting tool.

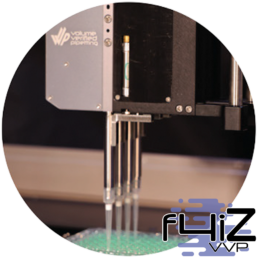

f4iz Pipetting Tool

4 channel (1×4) tool; independent z-axis

- 4 independent volumes

- Wide Dynamic Range: 1.5 μL – 1,250 μL/channel

- Independent z-axis motion per individual tip

- Independent access to variable spaced tubes and individual wells possible

- Verified and recorded in real-time

With independent Z-axis control, gain individual access to variable spaced tubes and

wells, allowing for precise handling of samples with unmatched flexibility. Whether

you’re working with diverse sample matrices or conducting intricate assays, the F4iZ

VVP pipetting tool delivers unparalleled performance, empowering you to achieve your

research goals with confidence.

Standard Technology (ST) Pipetting Tools

Traditional syringe-drive air-based pipetting; uniform volume across all channels. An economical solution for many liquid-handling applications such as plate stamping. Single, row and column tip pick up. For 24, 96, 384 & 1536-well plate-based liquid handling routines.

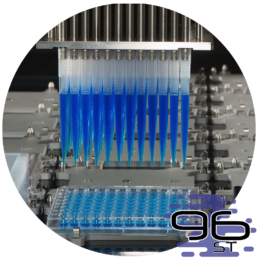

96ST Pipetting Tool

96 uniform volume channels; 8×12 array; fixed 9mm spacing

Our 96 ST Pipetting Tool allows the transfer of wells, rows, columns or entire 96 well plates across 96, 384 or even 1536 well plates. In this ST syringe based design, identical volumes are transferred in every channel. The dual disposable tip mandrel design provides options for low and high volume configurations. With replaceable CORE insert pipetting blocks, the 96 ST syringe pipetting tool is the most economical for high throughput liquid handling.

384ST Pipetting Tool

384 uniform volume channels; 16×24 array; fixed 4.5mm spacing

With the high loading force required to load 384 simultaneous tips, the Lynx is specifically engineered to load these tips from any worktable position. No specific loading areas or specialty tip loading tools required. Simply place the 384 tip box(es) in any microplate position and run your method with the versatility you expect from your Lynx LM Series Workstation.

96-well plates – Pipetting range by tool/tip type*

*lower volumes may be achieved under optimal conditions

384-well plates – Pipetting range by tool/tip type*

*lower volumes may be achieved under optimal conditions

1536-well Plate Pipetting

Positional Accuracy and Reproducibility

Linear drive motors coupled with x/y axes positional encoders provides unparalleled accuracy and zero drift over time. < 0.1 mm positional resolution allows robust pipetting to high-density 1536-well plates.

Multi-Core Pipetting Arm (MCPA)

Unlock the Future of Liquid Handling

Say goodbye to manual pipette changes and hello to seamless automation. With Dynamic Devices’ Multi-Core Pipetting Arm (MCPA), you can swap tools on-the-fly, boost your throughput, and streamline complex workflows — all without missing a beat.

Lynx Platform

Lynx incorporates a series of enabling technologies for robust performance and reduced maintenance.

Absolute positioning with Linear Magnetic Motors and Encoders

Linear motors and encoders offer enhanced positional accuracy, precision, and repeatability compared to traditional mechanical rota-tion-to-translation mechanisms like racks & pinions or belts & pulleys typically used in laboratory liquid handling instruments. Moreover, they contribute to higher speeds, decreased maintenance requirements, and improved performance in pipetting tools.

Low Maintenance Solid Mandrel Tip Loading

The Solid Mandrel (SM) tip adapters, designed for loading disposable pipette tips, have eliminated the necessity of maintaining high-maintenance components such as rubber O-rings and tip seals. By adopting SM tip loading, the requirement for a 3 or 6-month preventive maintenance service is avoided, as it excludes the most maintenance intensive component on the robot.

Flexibility with an Unrestricted Worktable

The Lynx worktable features SBS-compliant microplate footprints in each position, providing flexibility for organizing plates, tips, or disposables. With a robust chassis and vertical drive, the Lynx can load 96 or 384 tips from any of its 66 worktable locations. This versatility, along with a complete line of disposable tips in SBS free-standing tip boxes, creates a highly efficient and flexible worktable.

Open Design For Flexible Integration

The Lynx offers versatile integration possibilities ranging from basic pipette head grippers to 6-axis SCARA robots capable of reaching off the deck. Its open chassis design enables integration from all four sides, and it accommodates horizontal conveyor options and vertical incorporation through the work-table.

Lynx Platform Decks Sizes

Sizes & Capacities

Flexible, space-efficient decks to fit your ideal throughput and walk-away time; 5 models to choose from:

Dynamic Loading & Storage Integration

We’re excited to introduce to you the NEWEST member of the Dynamic Devices product line Qdex!

With the need for speed and ultimate flexibility, the NEW Qdex will solve your workflow bottlenecks holding up to 60 trays at a time.

As displayed at SLAS 2020, Qdex is available for continuous operation with dynamic loading giving you uncompromising performance.

Virtual Deck | Faster Access | Random Access | Batch Processing | Continuous Loading | Multi-User Availability | SBS & Custom Labware | 4x the capacity

No more waiting to load or unload plates or trays

Normalize 270 plates in less than 4 hours

Exchange a tray of 9 plates in 30 seconds

18 virtual deck positions available

Seamless Integration with Lynx Workstation

Dynamic Loading/Unloading of Trays

Holds up to 60 Trays at a Time

Head Gripper Tool

cost-effective solution for on-deck labware transport; fingers configured onto 96 or 384 head arms; plate stacking/unstacking, lidding/de-lidding plates, move mag and vac separation devices, discard empty tip boxes and more

Scanning

1D & 2D Scanning

integrated barcode scanning modules capable of efficient scanning of 1D and 2D barcodes on tubes and plates; affords highly secure sample tracking and chain-of-custody reporting

Instrument Control Software

Simplified Instrument Control

With Method Manager 4.0 (MM4), controlling your Lynx is made easy. MM4 provides a practical approach to method programming, worklist importing, runtime control, pipetting data exporting and diagnostics reporting. And no matter the size of your Lynx, all use the same MM4 software for consistency across the entire Lynx platform.

Lynx Certified Disposable Tips

Clear Tips

Lynx uses high-quality CLEAR disposable tips for all pipetting and liquid level detection, eliminating the need for expensive black polycarbonate tips. VVP flow sensor technology allows for robust LLD in both tubes and plates and can accommodate compromised samples containing clots, bubbles or foam. Several sizes and filtered/unfiltered versions are available

Standard Boxes

All Lynx-brand tips are housed in ANSI-standard containers, allowing for placement anywhere on the deck. Tip pick-up directly from sturdy tip boxes eliminates the need for dedicated racks or tip loaders.

INTERESTED IN STARTING A PROJECT TOGETHER?

WE’D LOVE TO HEAR FROM YOU.